Table of Contents

- Introduction

- Understanding Neopentyl Glycol

- What is Neopentyl Glycol?

- Applications of Neopentyl Glycol

- The Growing Demand for Neopentyl Glycol

- Increasing Use in the Paint and Coatings Industry

- Surging Demand in Plasticizers Production

- Choosing the Right Neopentyl Glycol Supplier

- Quality and Purity of the Product

- Reliability and Timely Delivery

- Customer Support and Technical Assistance

- The Role of Neopentyl Glycol Suppliers in the Market

- Ensuring Smooth Supply Chain Operations

- Contributing to Sustainable Practices

- Advantages of Partnering with a Reputable Neopentyl Glycol Supplier

- Access to High-Quality Products

- Competitive Pricing

- Innovation and Research

- Tips for Identifying a Reliable Neopentyl Glycol Supplier

- Research and Background Check

- Customer Reviews and Testimonials

- Industry Experience and Certifications

- Range of Products Offered

- Frequently Asked Questions (FAQs)

- What is Neopentyl Glycol used for?

- Is Neopentyl Glycol safe for use in food packaging?

- How can I store Neopentyl Glycol properly?

- Can Neopentyl Glycol be used in the production of pharmaceuticals?

- What makes Neopentyl Glycol an eco-friendly option?

Introduction

In recent times, the chemical compound Neopentyl Glycol (NPG) has been making waves across various industries. Its unique properties and diverse applications have sparked conversations in the market. As the demand for this compound continues to rise, the significance of reliable Neopentyl Glycol suppliers becomes apparent. In this article, we will explore the reasons behind the growing popularity of Neopentyl Glycol and shed light on the crucial role suppliers play in meeting this demand.

Understanding Neopentyl Glycol

What is Neopentyl Glycol?

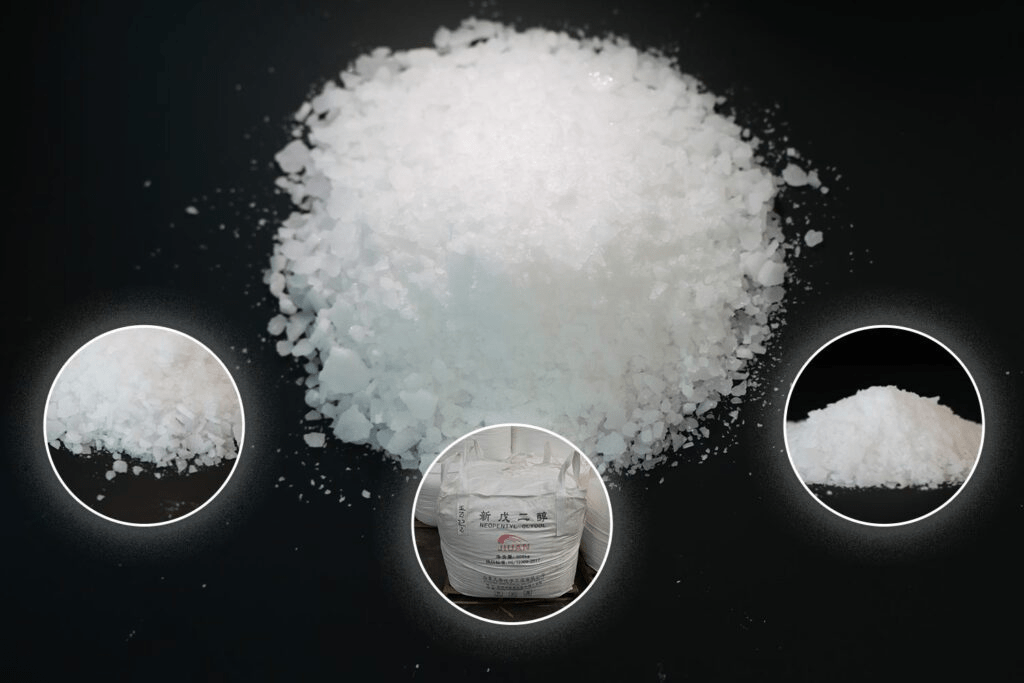

Neopentyl Glycol, commonly abbreviated as NPG, is a highly versatile organic compound with the chemical formula C5H12O2. It is a white, crystalline powder or flakes, and it is known for its excellent chemical stability and low volatility. NPG has found widespread applications in various industries due to its unique properties and benefits.

This compound plays a pivotal role in the production of high-quality paints and coatings, where it imparts essential attributes like hardness, gloss, and weather resistance. Its use as a key ingredient in paint formulations has led to an increased demand in the construction and automotive sectors.

Furthermore, Neopentyl Glycol is widely employed in the manufacturing of plasticizers, which are essential in enhancing the flexibility and durability of plastic materials. The expanding plastics industry has contributed significantly to the rising demand for NPG.

Applications of Neopentyl Glycol

Neopentyl Glycol (NPG) finds extensive applications across various industries, driven by its remarkable properties and versatility. Some of the key applications of Neopentyl Glycol include:

- Paints and Coatings: One of the primary uses of NPG is in the manufacturing of high-performance paints and coatings. It serves as a crucial building block in the production of alkyd resins, which are widely used in architectural coatings, industrial paints, and automotive finishes. The incorporation of NPG in these formulations enhances the coatings’ hardness, gloss, and weather resistance, resulting in durable and aesthetically pleasing finishes.

- Plasticizers Production: NPG plays a significant role in the plasticizers industry. Plasticizers are additives used to increase the flexibility and workability of plastic materials. Neopentyl Glycol-based plasticizers offer excellent compatibility with various polymer matrices and improve the mechanical properties of plastics, making them suitable for a wide range of applications, including wire insulation, vinyl flooring, and synthetic leather production.

- Synthetic Lubricants: Neopentyl Glycol is utilized in the production of synthetic lubricants due to its outstanding lubricating properties and thermal stability. Synthetic lubricants formulated with NPG offer enhanced performance in extreme temperature and pressure conditions, making them suitable for demanding applications in automotive, aerospace, and industrial machinery.

- Polyester Resins: NPG is a key component in the synthesis of polyester resins. These resins find extensive use in various applications, including fiberglass-reinforced plastics, coatings, adhesives, and composites. Polyester resins based on Neopentyl Glycol exhibit excellent corrosion resistance, electrical properties, and mechanical strength, making them ideal for a wide range of industrial and consumer goods.

The Growing Demand for Neopentyl Glycol

The popularity of Neopentyl Glycol has been on the rise due to its extensive utility. Two significant factors contributing to its increasing demand are:

Increasing Use in the Paint and Coatings Industry

The Paint and Coatings Industry has witnessed a substantial increase in the use of Neopentyl Glycol (NPG) in recent years. This trend can be attributed to the unique properties and advantages that NPG imparts to paints and coatings, making it a favored choice among manufacturers and consumers alike.

- Enhanced Performance: Neopentyl Glycol serves as a crucial building block in the formulation of alkyd resins, which are widely used in paints and coatings. Alkyd resins based on NPG exhibit exceptional performance characteristics such as excellent hardness, gloss, and weather resistance. These properties result in durable and long-lasting finishes that withstand harsh environmental conditions, making them ideal for both indoor and outdoor applications.

- Reduced Volatility and Low VOC Emissions: NPG-based coatings offer the advantage of low volatility, which translates to reduced volatile organic compound (VOC) emissions. VOCs contribute to air pollution and have adverse effects on human health and the environment. With increasing awareness and regulations on VOC emissions, the use of NPG in coatings has gained popularity as a more environmentally friendly option.

- Improved Environmental Resistance: Neopentyl Glycol enhances the environmental resistance of paints and coatings, making them more suitable for use in challenging conditions. Coatings formulated with NPG exhibit superior resistance to factors such as moisture, chemicals, and UV radiation, protecting surfaces and maintaining their appearance for extended periods.

- Wide Range of Applications: The versatility of Neopentyl Glycol extends to a variety of coatings applications. It is utilized in architectural coatings for residential and commercial buildings, industrial coatings for machinery and equipment, automotive coatings for cars and vehicles, and marine coatings for ships and offshore structures. This adaptability across different sectors has contributed to its increasing use in the paint and coatings industry.

Surging Demand in Plasticizers Production

The demand for Neopentyl Glycol (NPG) in plasticizers production has experienced a significant surge in recent times. Plasticizers are vital additives used to enhance the flexibility, workability, and performance of plastic materials. As the plastics industry continues to grow and diversify, the unique properties of NPG have made it a preferred choice for formulating high-quality plasticizers.

- Effective Plasticization Properties: Neopentyl Glycol’s molecular structure and functionality make it an excellent building block for plasticizers. When incorporated into plastic materials, NPG effectively reduces their glass transition temperature, allowing the plastics to become more pliable and easier to process during manufacturing. This increased flexibility and workability lead to the production of a wide variety of plastic products with different shapes and sizes.

- Compatibility with Diverse Polymers: NPG-based plasticizers exhibit excellent compatibility with a wide range of polymers, including polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP). This compatibility ensures that NPG can be incorporated into various plastic formulations, tailoring the properties of the plastic to meet specific requirements for different applications.

- Improved Mechanical Properties: The addition of Neopentyl Glycol-based plasticizers enhances the mechanical properties of plastics, such as tensile strength, elongation, and impact resistance. This results in more durable and resilient plastic materials suitable for a multitude of industries, including construction, automotive, and consumer goods.

- Reduced Migration and Volatility: Plasticizers based on Neopentyl Glycol offer the advantage of reduced migration and volatility. Migration refers to the process where plasticizers leach out of the plastic material over time, potentially causing undesirable effects on the surrounding environment or other materials in contact. NPG’s low volatility minimizes the emission of harmful substances into the air, contributing to a healthier and safer environment.

Choosing the Right Neopentyl Glycol Supplier

Selecting the right supplier is crucial to ensure a smooth supply chain and obtain high-quality products. Some key factors to consider when choosing a Neopentyl Glycol supplier are:

Quality and Purity of the Product

A reliable supplier should provide NPG with the highest level of purity, meeting industry standards and regulations. Quality assurance processes should be in place to guarantee consistent product excellence.

Reliability and Timely Delivery

A dependable supplier should have a track record of timely deliveries, ensuring uninterrupted operations for their customers.

Customer Support and Technical Assistance

Excellent customer support and technical expertise are essential for addressing any queries or concerns that may arise during product usage.

The Role of Neopentyl Glycol Suppliers in the Market

Neopentyl Glycol suppliers play a critical role in meeting the growing demand for this compound. Their contributions include:

Ensuring Smooth Supply Chain Operations

Suppliers are responsible for maintaining a stable supply chain, ensuring that Neopentyl Glycol reaches end-users efficiently and on time.

Contributing to Sustainable Practices

Reputable suppliers focus on sustainable sourcing and manufacturing processes, promoting eco-friendly practices throughout the industry.

Advantages of Partnering with a Reputable Neopentyl Glycol Supplier

Collaborating with a trustworthy supplier offers several advantages, such as:

Access to High-Quality Products

Partnering with a reputable supplier ensures access to top-notch Neopentyl Glycol products, meeting the required quality standards.

Competitive Pricing

Established suppliers often offer competitive pricing, enabling businesses to manage production costs effectively.

Innovation and Research

Leading suppliers actively invest in research and development, bringing forth innovative Neopentyl Glycol solutions.

Tips for Identifying a Reliable Neopentyl Glycol Supplier

When looking for a Neopentyl Glycol supplier, consider the following tips:

Research and Background Check

Thoroughly research potential suppliers to assess their reputation and credibility in the market.

Customer Reviews and Testimonials

Review customer feedback and testimonials to gain insights into the supplier’s service quality.

Industry Experience and Certifications

Look for suppliers with extensive industry experience and relevant certifications, ensuring their adherence to best practices.

Range of Products Offered

Consider suppliers with a wide range of products to meet your specific requirements.

Conclusion

In conclusion, the escalating demand for Neopentyl Glycol across diverse industries has captured the attention of professionals and businesses alike. Its versatility and unique properties make it a sought-after compound in the manufacturing world. To leverage the benefits of NPG fully, partnering with a reputable supplier is essential. By choosing a reliable Neopentyl Glycol supplier, businesses can ensure a smooth supply chain and access high-quality products, paving the way for sustainable growth.

FAQs

- What is Neopentyl Glycol used for?

Neopentyl Glycol is commonly used in the production of paints, coatings, and plasticizers due to its exceptional chemical properties. - Is Neopentyl Glycol safe for use in food packaging?

Yes, Neopentyl Glycol is considered safe for use in food packaging applications. - How can I store Neopentyl Glycol properly?

Store Neopentyl Glycol in a cool, dry place, away from direct sunlight and heat sources. - Can Neopentyl Glycol be used in the production of pharmaceuticals?

Neopentyl Glycol Supplier:Neopentyl Glycol is primarily utilized in the production of paints, coatings, and plasticizers and is not commonly used in pharmaceuticals. - What makes Neopentyl Glycol an eco-friendly option?

Neopentyl Glycol’s non-toxic nature and eco-friendly production processes contribute to its environmentally friendly status.