Introduction

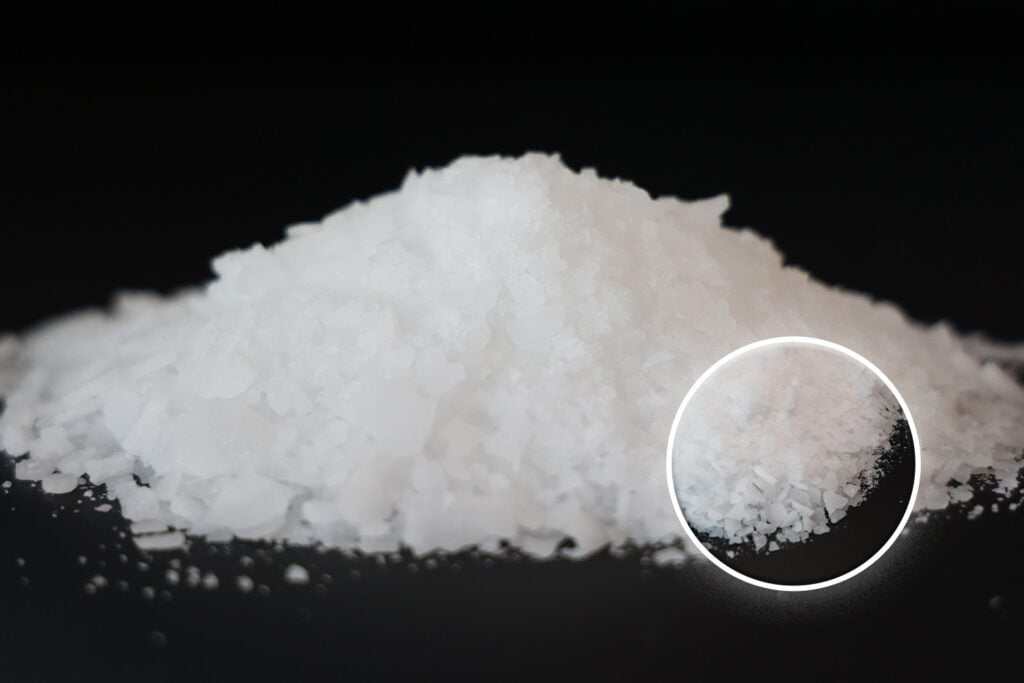

Five Outrageous Ideas For Your Neopentyl Glycol Production.Neopentyl glycol, commonly known as NPG, is a vital organic compound that finds extensive application across diverse industries such as paints, coatings, adhesives, and plastics. This versatile chemical is highly prized for its exceptional stability, low volatility, and resistance to heat and chemicals, making it a preferred choice for various manufacturing processes. As industries continue to seek innovative solutions and sustainable practices, the production of neopentyl glycol presents an exciting opportunity for advancements that can revolutionize the chemical landscape.

In recent years, the demand for neopentyl glycol has been steadily rising due to its unique properties and widespread applications. However, traditional production methods have often relied on petrochemical-based routes, which not only pose environmental concerns but also contribute to resource depletion. As industries strive to reduce their carbon footprint and adopt greener practices, there is a growing need for novel approaches to neopentyl glycol synthesis that emphasize sustainability without compromising on quality and efficiency.

Microbial Fermentation for NPG Synthesis

Microbial fermentation, a process commonly associated with the production of food and beverages, has emerged as an audacious and intriguing idea for neopentyl glycol (NPG) synthesis. Traditionally, NPG has been synthesized through petrochemical-based routes, which can be environmentally taxing and resource-intensive. However, with the advancement of biotechnology and genetic engineering, researchers and industries are exploring the untapped potential of microorganisms to biosynthesize valuable chemicals like neopentyl glycol.

At its core, microbial fermentation involves the controlled use of microorganisms such as bacteria, yeast, or fungi to convert organic materials into desired products. In the context of neopentyl glycol production, the idea is to engineer microorganisms to efficiently produce NPG from renewable feedstocks, thereby reducing reliance on non-renewable resources and minimizing the overall environmental impact.

The concept of using microbes to produce industrially significant chemicals is not new, but its application to NPG synthesis represents an exciting frontier. Through genetic manipulation, scientists can introduce specific genes into the microorganisms, enabling them to produce key enzymes that catalyze the conversion of raw materials into neopentyl glycol. This approach not only has the potential to streamline the production process but also presents an opportunity to tailor the product’s characteristics to meet industry-specific requirements.

Neopentyl Glycol Production:Supercritical Carbon Dioxide (SC-CO2) Extraction

Supercritical Carbon Dioxide (SC-CO2) extraction is an innovative and unconventional method that holds great promise for neopentyl glycol (NPG) production. This cutting-edge technique utilizes carbon dioxide in its supercritical state, a phase where it exhibits both gas-like and liquid-like properties, to extract and separate target compounds from raw materials. SC-CO2 extraction has gained significant traction in various industries due to its eco-friendly and non-toxic nature, making it an attractive alternative to conventional extraction methods.

The principle behind SC-CO2 extraction lies in manipulating carbon dioxide to surpass its critical temperature and pressure, creating a supercritical fluid with unique solvent properties. In this state, SC-CO2 can penetrate deep into the raw material matrix and solubilize the desired compounds, including neopentyl glycol, without leaving behind any harmful residues or impurities. Moreover, the solubility of specific compounds can be easily adjusted by varying the pressure and temperature, allowing for precise control over the extraction process.

One of the most significant advantages of SC-CO2 extraction is its environmental friendliness. Carbon dioxide, the primary solvent used in this method, is a naturally occurring, non-toxic gas abundant in the atmosphere. It poses no threat to human health or the environment and does not contribute to greenhouse gas emissions when properly handled and recycled. As a result, SC-CO2 extraction offers a sustainable and green approach to neopentyl glycol production, aligning with the growing demand for eco-conscious manufacturing processes.

Photochemical Conversion of Biomass-Derived Compounds

Photochemical conversion of biomass-derived compounds presents a groundbreaking and unconventional approach to neopentyl glycol (NPG) synthesis. In recent years, there has been growing interest in harnessing the power of sunlight to drive chemical reactions, especially in the context of sustainable and green manufacturing processes. This innovative idea explores the potential of utilizing renewable biomass-derived compounds as feedstocks for neopentyl glycol production, with the aid of photochemical reactions activated by solar energy.

At its core, photochemical conversion involves the use of light energy to initiate chemical transformations. In the case of biomass-derived compounds, these are organic materials obtained from renewable sources such as plants, agricultural residues, or waste biomass. These compounds are abundant and offer the advantage of being carbon-neutral, as the carbon dioxide released during their production is offset by the carbon dioxide absorbed during plant growth.

Electrochemical NPG Synthesis

Electrochemical NPG synthesis is a cutting-edge and promising idea that aims to revolutionize the production of neopentyl glycol (NPG) through the power of electrochemistry. Unlike traditional methods that often rely on harsh reaction conditions and energy-intensive processes, this innovative approach leverages the principles of electrochemical reactions to efficiently and selectively synthesize NPG with enhanced sustainability and precision.

At the heart of electrochemical NPG synthesis is the use of electricity to drive chemical transformations. Electrochemistry involves the exchange of electrons between electrodes and reactants in an electrolyte solution, leading to redox reactions that facilitate the conversion of raw materials into desired products. By carefully controlling the applied voltage, current, and reaction parameters, researchers can direct the electrochemical process to favor the formation of neopentyl glycol over other byproducts, achieving higher product purity and yield.

Catalytic Converters for Waste Utilization

Catalytic converters for waste utilization present a bold and transformative idea that seeks to revolutionize neopentyl glycol (NPG) production while addressing the pressing issue of waste management. Conventional methods of chemical synthesis often generate waste materials and byproducts, leading to environmental pollution and resource wastage. However, this innovative approach proposes the use of catalytic converters to transform waste materials from other chemical processes into valuable neopentyl glycol, fostering a circular economy and promoting sustainability.

The concept of catalytic converters draws inspiration from their established role in controlling emissions from vehicles and industrial processes. In the context of NPG production, these converters act as catalysts to facilitate the conversion of waste compounds into desired neopentyl glycol. By leveraging the inherent reactivity and selectivity of the catalysts, the process can efficiently convert the waste stream into a valuable chemical resource, reducing the environmental burden associated with waste disposal.

Conclusion

In conclusion, the ideas presented in this article have shed light on five outrageous and inventive approaches to neopentyl glycol (NPG) production, each with the potential to redefine the landscape of the chemical industry. From exploring microbial fermentation to harnessing solar energy through photochemical conversion, and from leveraging electrochemistry to repurposing waste materials with catalytic converters, these groundbreaking concepts offer exciting possibilities for a more sustainable, efficient, and environmentally responsible future.

Traditional methods of NPG synthesis have served industries well, but with the growing emphasis on sustainability and eco-conscious practices, these innovative ideas open new doors of opportunity. Embracing such transformations not only addresses environmental concerns but also unlocks pathways for cost-effectiveness, energy savings, and waste reduction.

FAQs

- Is neopentyl glycol hazardous to handle?

Neopentyl glycol is generally considered safe to handle when proper safety measures are followed. However, it is essential to use appropriate personal protective equipment and adhere to handling guidelines to minimize any potential risks. - Can microbial fermentation be cost-effective for NPG production?

Yes, microbial fermentation can be cost-effective in the long run, especially if renewable feedstocks are utilized. Though initial setup costs might be higher, the sustainable and renewable nature of this method can lead to significant savings over time. - What advantages does SC-CO2 extraction offer over conventional methods?

SC-CO2 extraction is advantageous because it does not require the use of harmful solvents, ensuring a safer and greener process. Additionally, it can be performed at lower temperatures, preserving the integrity of the product and reducing energy consumption. - How can electrochemical synthesis improve NPG production?

Electrochemical synthesis allows for precise control, leading to higher product purity and improved yields. Moreover, it can be coupled with renewable energy sources, making the process more environmentally friendly. - What waste materials can be utilized for NPG production through catalytic converters?

Various waste materials from other chemical processes can potentially be used, including certain byproducts and unused compounds. The use of catalytic converters allows for the conversion of these wastes into valuable neopentyl glycol, promoting sustainability and resource efficiency.