What is Neopentyl Glycol?Neopentyl glycol, commonly abbreviated as NPG, is a versatile organic compound used in various industrial applications. It is a polyhydric alcohol with the molecular formula C5H12O2 and is also known by other names such as 2,2-dimethyl-1,3-propanediol and neopentyl alcohol. In this article, we will explore the properties, production process, advantages, disadvantages, environmental impact, and the future prospects of neopentyl glycol.

What is Neopentyl Glycol:Understanding Neopentyl Glycol

Chemical Structure and Properties

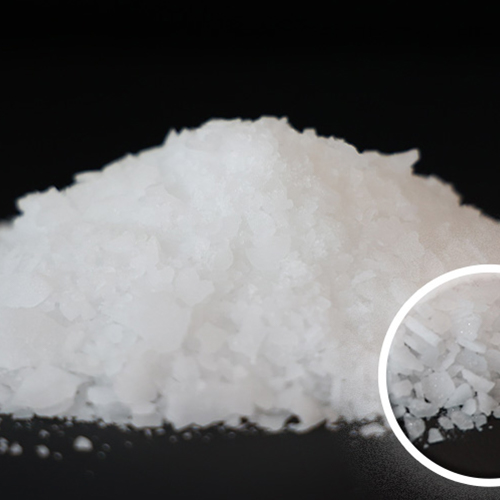

Neopentyl glycol is a white, crystalline solid with a high melting point. Its unique chemical structure, characterized by branching and the absence of reactive functional groups, makes it exceptionally stable and less prone to reactions such as oxidation or polymerization. This stability contributes to its widespread use in various applications.

Industrial Applications

Neopentyl glycol finds extensive use in the manufacturing of polyester resins, which are essential components in the production of coatings, adhesives, and elastomers. The polyester resins based on NPG offer enhanced performance, including improved flexibility, weather resistance, and durability. Moreover, NPG-based resins are vital in the production of powder coatings, ensuring a smooth and high-quality finish.

The Production Process of Neopentyl Glycol

Synthesis from Isobutyraldehyde

The synthesis of neopentyl glycol typically starts with isobutyraldehyde, an organic compound derived from propylene. Isobutyraldehyde undergoes a catalytic reaction to form neopentyl glycol as a condensation product.

Catalytic Hydrogenation

The next step involves catalytic hydrogenation, where the condensation product is subjected to hydrogen gas in the presence of a suitable catalyst. This process converts the intermediate product into neopentyl glycol.

Distillation and Purification

After hydrogenation, the crude neopentyl glycol is purified through distillation to remove any impurities and achieve the desired level of purity, usually above 99%. The purified NPG is then ready for various industrial applications.

Advantages and Disadvantages of Neopentyl Glycol

Advantages

- Excellent Stability: Neopentyl glycol’s stability ensures the longevity of products, making them more reliable and durable.

- Enhanced Performance: NPG-based polyester resins offer improved properties, such as flexibility and weather resistance, compared to conventional alternatives.

- Sustainable Choice: Its production process generates lower emissions and waste, aligning with sustainable manufacturing practices.

Disadvantages

- Cost: The production process of neopentyl glycol can be relatively expensive, affecting the overall cost of products that utilize NPG-based resins.

Environmental Impact of Neopentyl Glycol

Neopentyl glycol demonstrates a positive environmental profile due to its stable nature and lower emissions during its production process. Industries using NPG can potentially reduce their carbon footprint and adopt more eco-friendly practices.

Neopentyl Glycol in the Future

Sustainable Manufacturing

As environmental concerns grow, the demand for sustainable manufacturing processes will rise. Neopentyl glycol, with its favorable environmental attributes, is likely to play a more significant role in various industries seeking eco-friendly alternatives.

Expanding Applications

The versatility of neopentyl glycol makes it an attractive candidate for research and development, leading to new applications and markets. As technology advances, NPG may find use in innovative products beyond its current applications.

Conclusion

Neopentyl glycol, a stable and versatile polyhydric alcohol, has become a vital component in various industries, particularly in the production of polyester resins. Its unique properties, enhanced performance, and sustainable attributes make it a preferred choice for many applications. As the world moves towards eco-friendly solutions, neopentyl glycol’s significance is likely to grow further, paving the way for a more sustainable and innovative future.

FAQs

- Is neopentyl glycol toxic?

Neopentyl glycol is generally considered safe for industrial use and does not pose significant toxicity risks when handled appropriately. - Can neopentyl glycol be used in food or personal care products?

Neopentyl glycol is primarily used in industrial applications and is not commonly found in food or personal care products. - What are the alternative names for neopentyl glycol?

Neopentyl glycol is also known as 2,2-dimethyl-1,3-propanediol and neopentyl alcohol. - Is neopentyl glycol derived from renewable sources?

While neopentyl glycol can be produced using renewable sources, most commercial production methods involve petrochemical feedstocks. - How does neopentyl glycol contribute to sustainable manufacturing?

Neopentyl glycol’s stable structure and lower emissions during production align with sustainable manufacturing practices, making it an environmentally friendly choice for various industries.